Background

Green building technology is used to develop environmentally responsible and efficient building structure. To develop such structures; construction materials play a vital role and these are known as green building materials. Green building materials are responsible for sustainability and efficiency of a green building from design to demolition. These materials are also produced or selected as they consume less energy. Demand for green building materials have seen significant growth in recent years. Advanced materials such as cellulose, cotton, fiberglass and mineral wool are in great demand in the construction industry for insulation purpose. These materials are also eco-friendly and less toxic.

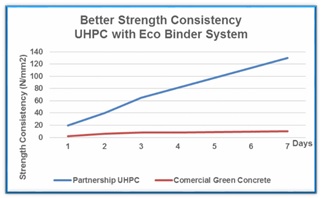

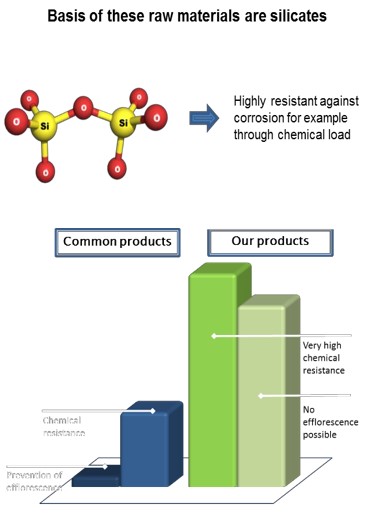

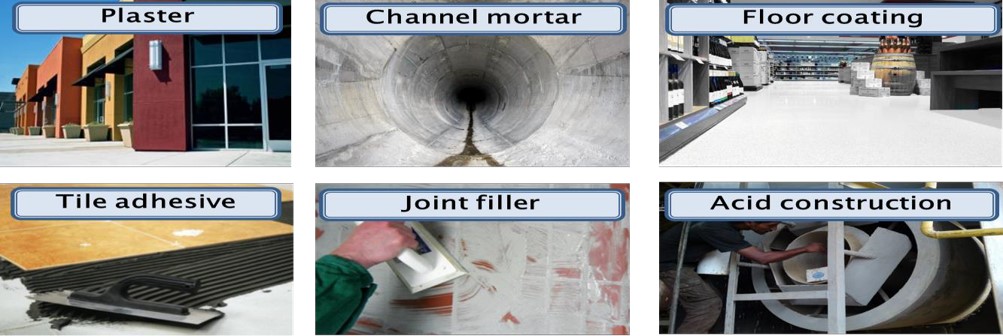

Our technology partner has significant experience of developing dry mortar, silicate and green concrete based building material products, using advanced chemistry and technology which has resulted in a large portfolio of products: